- Home

- ATEX

Potentially explosive atmospheres: important information

WHAT IS ATEX?

ATEX is an abbreviation for “Atmosphere Explosible”. At the same time, ATEX is the abbreviated name of the European Directive 2014/34/EC concerning the placing on the market of explosion-proof electrical and mechanical equipment, components and protective systems.

The ATEX code has been implemented as a voluntary standard since 1 March 1996. These rules are imperative for electrical and electronic equipment used in environments subject to explosion hazards sold at EC since 1 July 2003. From this date on, all products that are sold for use in explosive atmospheres must be ATEX approved and carry the symbol.

Product directive 94/9/EC defines the manufacturers' obligations.

Personal protection 99/92/EC defines the users' obligations.

Prerequisites for equipment certification:

- Self ignition feature

- To work in an environment with potentially explosive atmosphere

- Work in normal atmospheric conditions

The Regulations apply to all equipment, whether electrical or mechanical, including protective systems designed for use in explosive atmospheres. Remember that ATEX is only a legal requirement within the EU and EFTA countries so unless you are doing a project within the EU, legally you have nothing to be concerned with.

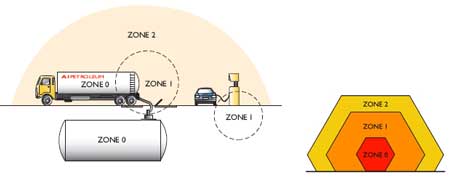

Classification of Explosive Atmosphere

For gases, vapours and mists the zone classifications are:

Zone 0 A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is present continuously or for long periods or frequently.

Zone 1 A place in which an explosive atmosphere consisting of mixture with air of dangerous substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

Zone 2 A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only

Fields of Application

Chemical Analysis Laboratories

mining, ports

petrochemical industry

Cosmetic Manufacturers

Oven and Static Powder Coating Ambients

Laboratory with Gas Environments, etc. Facilities

Parts of the battery manufacturing

Ethylene-used dress cleaners

Workplaces with plastic injection production

Animal feeding network, storage

Leather dyeing and manufacturing

Box etc. parts of paper packaging factories

Cotton Storage

Thinner and paint manufacturing and storage

Parts of furniture production places

Pressure Control Rooms

Drilling and Piping Equipment

refrigeration industry

warehouses

Food Manufacturing (Powder)

Classification of an explosive atmosphere

The are classified into groups and zones according to directive 99/92/CE and IEC standads as follows:

| Destination | Categories/presence of potntially explosive atmosphere | Hazardous zones | Atmosphere |

|---|---|---|---|

| Group I Mines | M1 and M2 | Gas and dust | (G & D) |

| 1 Permanent or frequent | Zone 0: gas and vapour Zone 20: mist and dust | G D |

|

| Group II surface Industries | 2 Occasional | Zone 1: gas and vapour Zone 21: mist and dust | G D |

| 3 Rare | Zone 2: gas and vapour Zone 22: mist and dust | G D |

| CENELEC | IEC | Gas: symbol of the types of protection | CENELEC/EC | Powder: symbol of the types of protection |

|---|---|---|---|---|

| EN 60079-0 | IEC 60079-0 | General rules | IEC/EN 61241-0 | General rules |

| EN 50015 | IEC 60079-6 | o-oil immersion | IEC/EN 61241-1 | tD-protection by enclosures |

| EN 50016 | IEC 60079-2 | p-pressurised enclosures | IEC/EN 61241-4 | pD-protection by pressurisation |

| EN 50017 | IEC 60079-5 | q-powder filling | IEC/EN 61241-11 | ID-protection by intrinsic safety |

| EN 60079-1 | IEC 60079-1 | d-flameproof enclosures | IEC/EN 61241-18 | mD-protection by encapsulation |

| EN 60079-7 | IEC 60079-7 | e-increased safety | ||

| EN 50020 | IEC 60079-11 | i-intrinsic safety | ||

| EN 60079-15 | IEC 60079-15 | n-type of protection ‘n’ |

Enclosures are certified as components . They will be assembled with other ATEX electrical, pneumatic and hydraulic components, among others to form a final solution which, in turn , must be ATEX – certified an subject to a declaration of conformity.

Degree of Protection

In hazardous areas, equipment is required to offer a minimum degree of protection of IP 54, but it can be tested or certified with a higher degree of protection.

Fields of Application

- Chemical Analysis Laboratoriesmining, ports petrochemical industry

- Cosmetic Manufacturers

- Oven and Static Powder Coating Ambients

- Some Parts of Oil Refinery

- Laboratory with Gas Environments, etc. Facilities

- Parts of the battery manufacturing

- Ethylene-used dress cleaners

- Workplaces with plastic injection production

- Animal feeding network, storage

- Leather dyeing and manufacturing

- Box etc. parts of paper packaging factories

- Cotton Storage

- Sulfur Storage

- Thinner and paint manufacturing and storage

- Quilt manufacturing

- Parts of furniture production places

- Pressure Control Rooms

- Drilling and Piping Equipment refrigeration industry

- Warehouses

- Food Manufacturing (Powder)